Navigating the World of Teak in 2025

As 2024 drew to a close, illegal teak dominated headlines across yachting industry media, highlighting growing scrutiny of regulatory compliance in relation to the importation of Myanmar teak in violation of EUTR and UK timber regulations. This development intensified concerns about non-compliance with the European Timber Regulation (EUTR), spotlighting the challenges the industry faces in ensuring sustainable and legal timber sourcing.

Furthermore, the broader and more stringent EUDR (EU Deforestation Regulation) is set to be implemented by 30 December 2025 for large companies and 30 June 2026 for micro- and small companies. Under the European Union Deforestation Regulation (EUDR), a large company is defined as one that meets at least two of the following criteria: more than 250 employees, an annual turnover exceeding €50 million, or an annual balance sheet total exceeding €43 million. In contrast, a small company is defined as one with fewer than 50 employees and either an annual turnover or an annual balance sheet total not exceeding €10 million.

This will introduce a requirement for any operator or trader placing commodities on the EU market (or exporting from it) to prove they did not contribute to forest degradation or recently deforested land – including a requirement for companies to provide geolocation data down to a specific plot of land for each tree felled. With all of this in mind, it can feel like there is more to navigate than ever where sourcing teak is concerned.

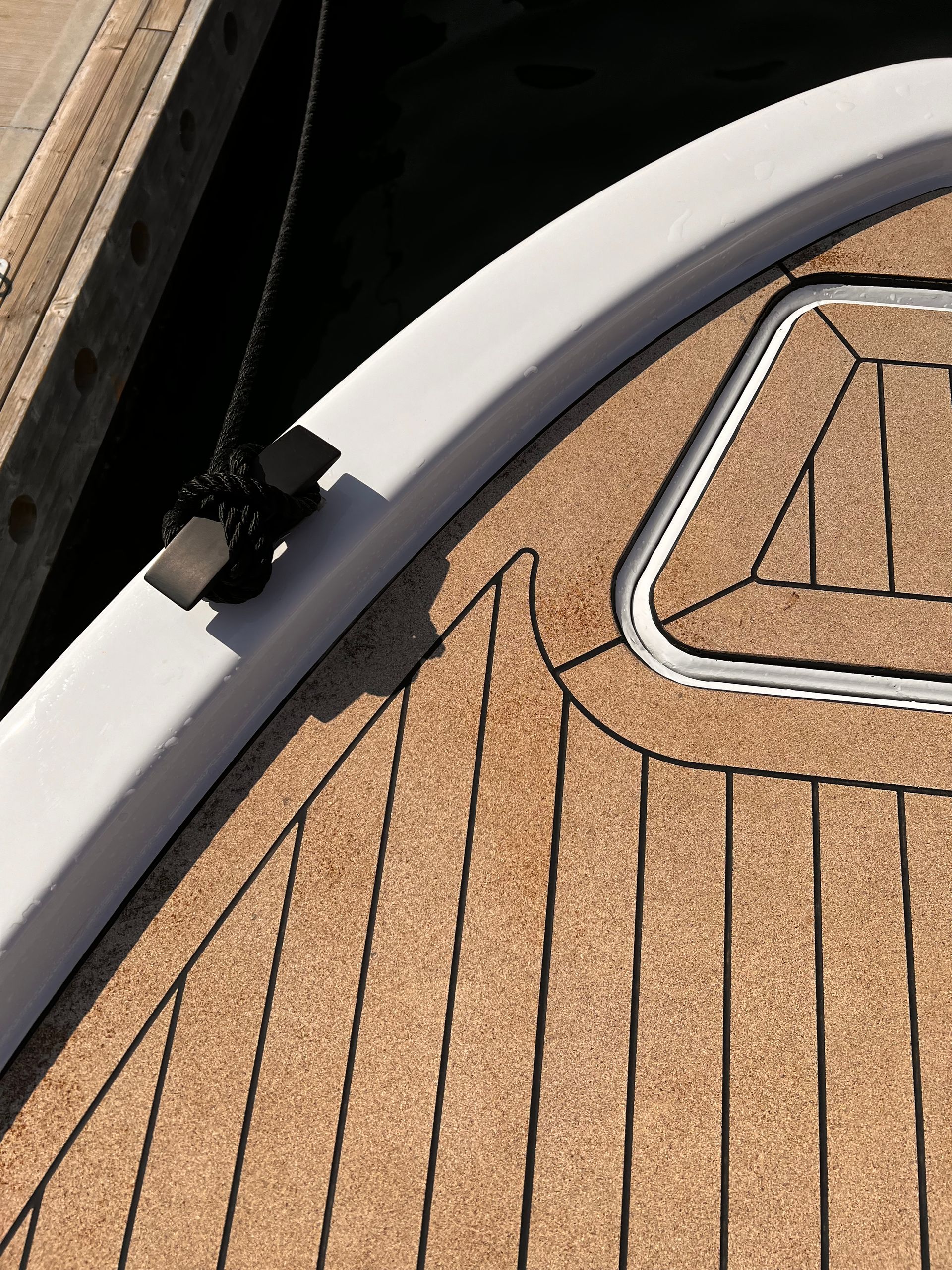

Depending on the preferences of each project and owner, high-quality, sustainable alternatives to teak (such as polyurethane composite decking or cork decking) are also available – these can be explored here and here. However, many superyacht owners are traditional by nature and still have a strong preference for the classic, warm look of teak. If it is teak which is required, how can you ensure that your teak is sourced legally?

Mike Doyle, Wood Sourcing Manager at TDS, emphasizes the importance of ensuring compliance when selecting a teak decking company. He advises focusing on the company’s adherence to international regulations, such EURT / EUDR or other relevant laws, and verifying their sourcing practices to ensure the timber is legally harvested and traceable. Proper due diligence in this area can help you avoid serious legal or regulatory issues down the line.

Understand Relevant Legislation & Regulations

Make sure you are familiar with the relevant legislation and regulations associated with teak and that the companies you are buying from are in compliance with EUTR /EUDR. This requires companies to exercise due diligence in sourcing timber to ensure that it has been harvested legally according to the laws of the country of origin.

Due Diligence System

A due diligence system (DDS), as required under the EUTR and EUDR, is a structured process designed to ensure that timber and related products are sourced legally and responsibly, without contributing to deforestation. It involves gathering detailed information about the origin of the wood, such as the country of harvest, the tree species, and supporting documentation to verify legality.

The system also includes assessing the risks associated with the supply chain, such as whether the wood comes from regions with weak enforcement of environmental or forestry laws. If any risks are identified, companies must take appropriate actions to reduce or eliminate them, such as seeking additional documentation or switching to more reliable suppliers.

This approach promotes sustainable practices and helps companies comply with regulations while protecting global forests.

Carry Out Regular Audits and Monitoring

To ensure compliance with their due diligence system, companies must conduct regular audits of their supply chains. This should encompass both internal audits (in which they periodically review internal processes and supplier compliance with legal requirements) and third-party audits.

In third–party audits, companies engage independent auditors who specialize in forestry and sustainability to assess compliance with EUTR and other relevant standards.

Train Employees and Stakeholders

Training is vital to ensure that all employees involved in procurement, sales and supply management understand the importance of sourcing legal timber. These programs should encompass the implications of illegal logging, best practices for verifying supplier claims and specifics of EUTR / EUDR compliance.

Engage with Certification Programs

To demonstrate your commitment to sustainable sourcing practices, companies can participate in recognized certification programs like the Forest Stewardship Council (FSC) or Program for the Endorsement of Forest Certification (PEFC). These will require adherence to strict guidelines for sustainability and legality.

Establish Clear Policies and Procedures

Develop clear policies for timber sourcing which outline your commitment to both legality and sustainability. These should be readily available to suppliers and communicated throughout your organization.

Collaborate with Industry Groups and NGOs

Collaboration is key! Engaging with non-governmental organizations (NGOS), industry groups and other stakeholders will bolster your resources and support and offer insights for implementing best practices for legal timber sourcing. It can also improve transparency within supply chains.

Keep Informed About Changes in Legislation

It’s crucial to stay updated on the latest timber regulations, such EUTR or EUDR and international agreements on forest management. These regulations are constantly evolving and understanding them ensures that the teak used in your deck is legally sourced and compliant with current laws.

Work closely with your supplier to confirm they are monitoring changes in legislation and have systems in place to meet compliance standards. Ensure they can provide documentation verifying the legality of their timber and demonstrate a commitment to sustainable sourcing practices.

By staying informed and partnering with suppliers who prioritize compliance, you can minimize risks and contribute to responsible forest management efforts.

Finally, Mike’s takeaway message would be:“If you need to hire external help to ensure your timber is compliant, just do it! A third-party company like Preferred by Nature or Double Helix will do a lot of the leg work for you.

ALL PRODUCTS