The questions you should be asking when shopping for a deck

When it comes to selecting a company for your new deck, transparency and trust are essential. While we at Teakdecking Systems believe in the superior quality and craftsmanship of our decks, we also understand that we are not the cheapest option. While cost is an important factor, it’s equally crucial to consider the long-term value and durability of your investment.

If you decide not to entrust us with your new deck, we strongly encourage you to do your due diligence and ask the right questions before committing. Our top priority is ensuring you make an informed decision, no matter whom you choose to work with. A new deck is a significant investment and balancing cost with quality and durability is key to avoiding costly mistakes down the line. To help you navigate this process, here are six crucial considerations to guide your decision-making process:

1. Research the Company’s Reputation

The first step in evaluating a decking company is to research its reputation. A quick online search can provide valuable insights into their track record through reviews, ratings, and testimonials from fellow yacht owners. Social media groups, forums, and word-of-mouth recommendations are also great sources of information. Pay close attention to any recurring themes in feedback—positive or negative—as they often reveal the company’s strengths or potential red flags.

2. Understand the Quality of the Teak

Not all teak is created equal. High-quality, seasoned old-growth teak is far superior to plantation or fast-growing teak. Old-growth teak has tighter growth rings, which make it denser, less permeable, and significantly more durable. Plantation teak, while more readily available, lacks these qualities and may not hold up as well in the long term. Knowing what kind of material you’re putting on your yacht will ensure you make a well-informed investment.

3. Verify the Legality and Availability of Materials

Legal sourcing of teak is not only an ethical concern but also impacts project timelines. Some companies may not stock the teak they use, instead purchasing it only when an order is placed. This could lead to delays, particularly if the company encounters sourcing challenges. Ensure the company you choose has legal teak readily available in their possession. This not only guarantees compliance with international laws but also reduces the likelihood of unforeseen delays in your project.

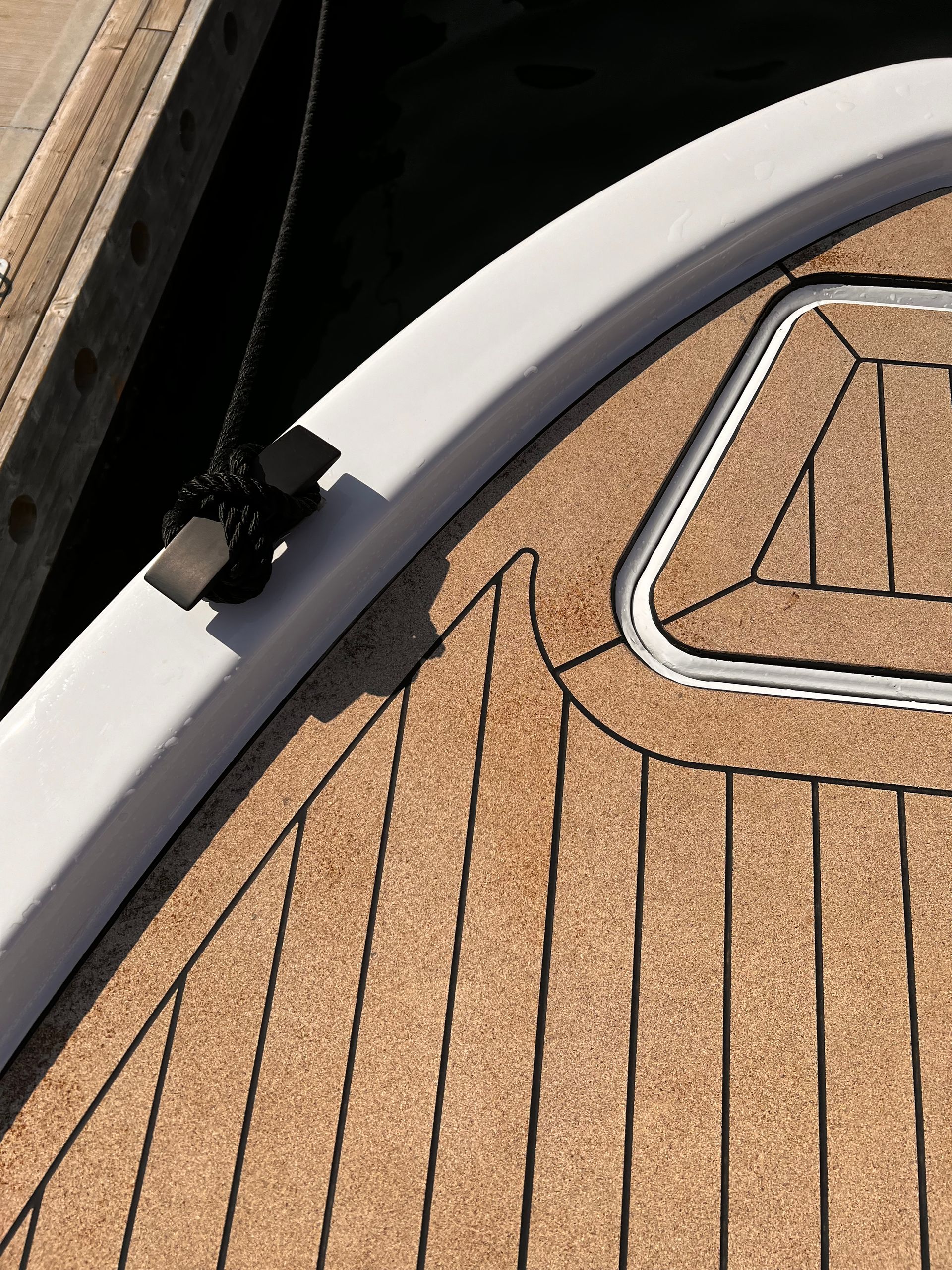

4. Compare Decking Materials

While teak is a popular choice for yacht decking, there are alternatives like EVA foam, PVC, Polyurethane, and cork that you may consider. Each material has its own pros and cons in terms of cost, durability, and appearance. For instance, EVA foam is lightweight and budget-friendly but lacks the longevity of teak, while PVC and Polyurethane offer varying levels of durability and cost-effectiveness. Carefully evaluate these options and discuss them with the company to determine the best fit for your needs and budget.

5. Review Past Projects and Current Workload

A company’s previous work speaks volumes about its capabilities and standards. Request to see examples of past projects, ideally ones similar to your vessel, to gauge their expertise. Additionally, inquire about their current workload. If a company is overbooked, your project could face delays, leaving your boat out of commission longer than expected. Asking for a clear manufacturing and installation timeline can help you set realistic expectations and plan accordingly.

6. Select a Reputable Yard

Where the work is performed is just as important as who performs it. Opt for a reputable yard that has experience handling yacht projects. A good yard can coordinate with subcontractors, enabling multiple tasks to be completed simultaneously, which saves time and ensures a smoother process overall. Effective project management is crucial in these situations, so ensure the yard has a proven track record of handling yacht renovations.

7. Warranty & Service

When evaluating decking companies, it is important to check if they offer a warranty and ask detailed questions about its coverage. Does it cover both materials and installation? What is the duration, and are there any conditions or exclusions? Clarify where warranty work will be carried out and any associated costs, such as transport, subsistence, lodging, and logistics required for repairs.

8. Global Service

For yacht owners constantly on the move, choosing a company with reliable global support is essential. Evaluate the company's operational reach and its ability to respond and travel to your vessel if needed. For total peace of mind, TDS decks are covered by a worldwide warranty, ensuring customers receive top-tier service and support wherever they are.

Final Thoughts

Choosing the right company for your yacht’s decking is a decision that shouldn’t be taken lightly. Transparency, reputation, and quality should be your top priorities when evaluating potential companies. By asking the right questions and thoroughly researching your options, you avoid costly mistakes and ensure your deck meets your expectations in both quality and longevity.

While cost is always a factor, remember that value is about more than just the upfront price, it’s about the durability, craftsmanship, and long-term performance of your deck. A well-informed decision will not only protect your investment but also enhance your enjoyment of your yacht for years to come.

ALL PRODUCTS